INDIA - WEST COAST

KAOLIN

-

Crude China Clay: Emphasized for its basic properties and versatility in a range of industrial uses.

-

Levigated Kaolin Clay & Hydrous Kaolin Powder: These are purified forms that are highlighted for high-end applications that demand high quality and minimum impurities.

-

Kaolin Noodles & Powder: Particularly suited for ceramic glazes due to its rheological and chemical properties (low iron and titanium content).

Production capacity 10.000-15.000 tons per month

Packing in specialised Big Bags or Bulk

Shipping in Big Bags in Container or bulk ex Mundra Gujarat India Port

Minimum Order quantity : 100 tons

Our price range is determined by quantity, delivery terms, and the specifics outlined in the contract.

Prices can also be affected by currency fluctuations and exchange rate

changes, which can lead to price variations.

-

China Clay (Crude Kaolin):

-

Key properties:

-

It does not swell in water.

-

It can withstand high temperatures.

-

It enhances the strength and durability of materials it is mixed with.

-

It reduces crack tendency in finished products.

-

It improves impact resistance and surface finish.

-

-

These properties make their China clay suitable for various industrial applications.

-

-

Levigated Kaolin Clay & Hydrous Kaolin Powder:

-

We offers a range of high-quality levigated kaolin clay in both lump and hydrous powder form.

-

Their production process includes advanced washing technology and stringent quality control to remove impurities like silica, iron, and titanium.

-

Key features include:

-

High purity.

-

Advanced washing technology.

-

Consistent quality.

-

Impurity removal.

-

-

-

Kaolin Noodles & Powder:

-

B&P fabricates kaolin noodles and powder from carefully selected mined, uncooked kaolin.

-

The product is characterized by its:

-

"Floor chemistry of the particles"

-

Specific rheological properties

-

Low content of iron oxide (Fe2O3) and titanium dioxide (TiO2)

-

-

These characteristics make the kaolin "nicely appropriate" for ceramic glaze applications.

-

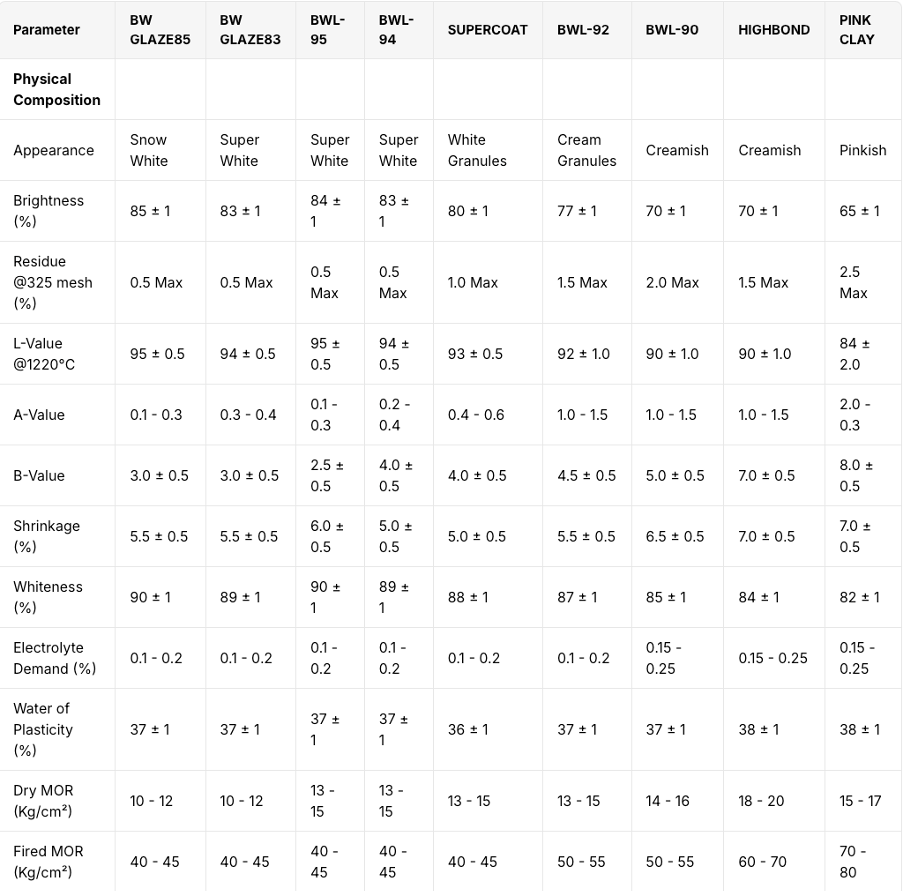

Analysis and Application Here is a summary: •Whiteness and Brightness: The "BW GLAZE" and "BWL" series (especially BW GLAZE85 and BWL-95) have the highest whiteness and brightness, making them suitable for glazes where a pure white base is needed. "Supercoat" is good as well, but in granule form •Color: The "PINK CLAY" has the lowest whiteness and a pinkish appearance, indicating the presence of coloring minerals. It could be used to create pink or reddish hues in glazes.The BWL-90, HIGHBOND are creamish which could be used for colored effect. •Residue: Higher residue indicates coarser particles. The "BW GLAZE" and "BWL" series have the lowest residue, indicating finer particle size, useful for smooth glaze finishes. •Strength (MOR): "HIGHBOND" exhibits the highest dry and fired MOR, which suggests it would be suitable for glazes requiring higher strength and durability. •Chemical Composition: The "PINK CLAY" has a higher iron oxide (Fe₂O₃) content, which contributes to its color. It also has a higher silica content. The alumina content is generally consistent across most types, except for "PINK CLAY," which is slightly lower. •Shrinkage: The kaolins generally have similar shrinkage, but this parameter should be considered based on the specific application and firing temperature. Potential Application based on quality : •BW GLAZE85 & BWL-95: Best suited for white or light-colored glazes where high brightness and whiteness are essential. Ideal for tableware and decorative items. •SUPERCOAT: Suitable for general-purpose white glazes, with slightly lower brightness than the BW GLAZE grades. •BWL-90 & HIGHBOND: Suitable for glazes where a higher strength and durability are needed, such as in industrial ceramics or tiles. The creamish color may influence the final glaze color. •PINK CLAY: Best for creating pink, red, or brownish glazes. Could also be used in blends to achieve unique color effects. It requires careful control due to its higher iron content, which can affect the glaze's firing behavior. Remember to consider other factors such as firing temperature, glaze formulation, and desired surface finish when selecting the appropriate type of kaolin clay.